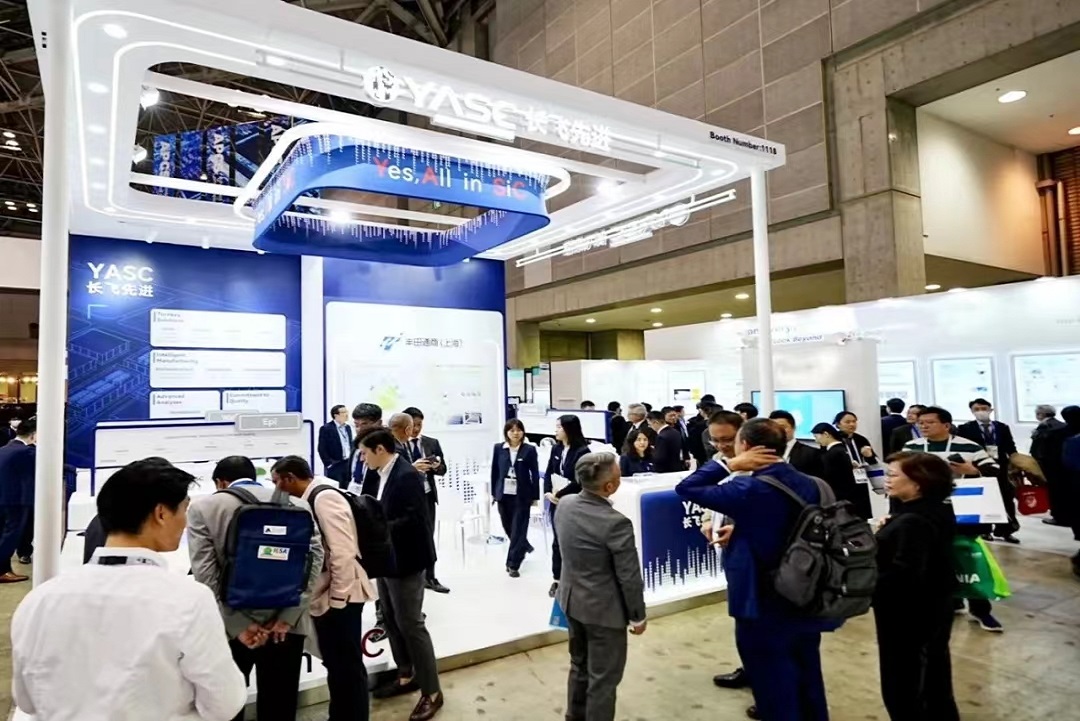

Good news kept pouring at the beginning of the new year — YASC successfully completed the renewal audit of international automotive quality management standard IATF 16949, and its in-house 1200V 15mΩ SiC MOSFET product smoothly passed the AEC-Q101 automotive-grade reliability qualification. This is an important step for YASC in automotive electronics, indicating that the company has scaled new heights in automotive quality management and product reliability.

01 IATF 16949: The “Gold Standard” in the Global Automotive Industry

IATF 16949 is a recognized international standard for automotive quality management systems. Based on ISO9001, it is added with technical specifications for the automotive sector, emphasizing defect prevention and the reduction of quality variation and waste easily arising in the automotive parts supply chain. The standard is clearly targeted and applicable only to vehicle manufacturers and their direct auto parts makers.

As silicon carbide (SiC) power devices continue to expand in the automotive application market, customers also constantly raise the requirements for chipmakers’ quality systems. To further improve its quality management level and especially meet the needs of automotive customers, YASC has actively carried out trainings on IATF16949, VDA6.3 quality systems and quality tools in recent years to strengthen understanding and practices of quality system requirements among all employees.

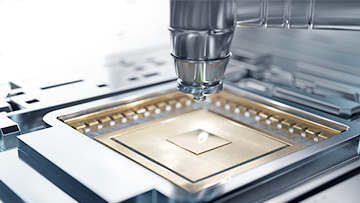

The renewal audit was conducted by internationally renowned certifier TÜV Rheinland, with the certification scope expanding from manufacturing power devices and power modules to designing and manufacturing power semiconductors. The certification is highly authoritative and widely accepted in the world. The successful passing of the audit not only demonstrates YASC’s outstanding strength in quality management, but also lays a solid foundation for its continued development in the automotive market.

02 AEC-Q101: The Automotive-grade Reliability Standard

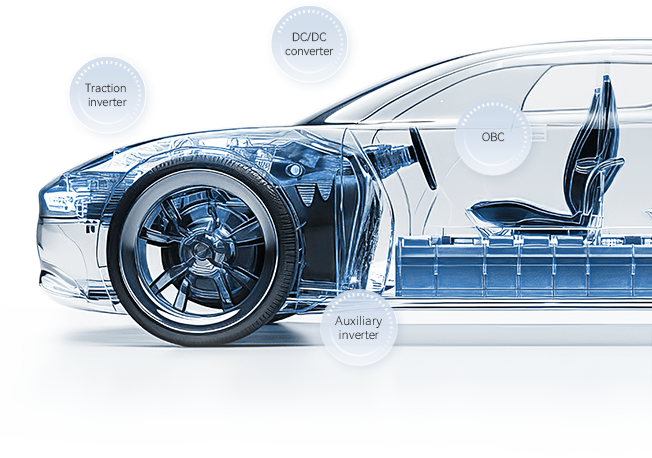

The special status of being automotive-grade cannot be overlooked in the electronics application market. Automotive-grade components must have higher reliability, durability and safety to ensure that they can operate in complex and volatile operating environments, such as extreme conditions including high temperature, low temperature, humidity, vibration and electromagnetic interference. Devices that are not certified for reliability may cause system failures or even pose serious safety hazards. The AEC-Q101 qualification is quality reliability evaluation for discrete semiconductors (such as diode, TVS tube, MOSFET and IGBT). It is a “certificate of access” for devices to the automotive market, and a symbol of high reliability.

The SiC MOSFET product, passing the AEC-Q101 automotive-grade qualification, is based on YASC’s Gen3 SiC MOSFET design and process platform with fully independent intellectual property rights (IPRs), the foremost in China in terms of specific on-resistance (Ronsp) and gate charge (Qg). It features very low switching loss and conduction loss, and can significantly boost performance of inverters and other application devices.

Taking the opportunity of the certifications, YASC will continue to increase investment in technology research and development, and unremittingly enhance quality management capabilities, while accelerating product iteration and upgrading. Looking ahead, it will develop higher-performance SiC power devices for new energy vehicles and more industry customers, and make positive contributions to the transformation and upgrading of manufacturing industry.