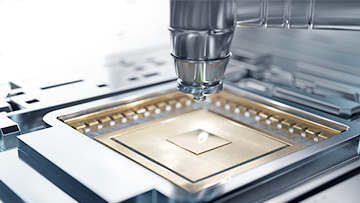

Failure Analysis Lab mainly conducts analysis using electrical testing and a variety of advanced physical, metallographic and chemical analysis techniques, in combination with specific circumstances before and after the component failure and relevant technical documents, to verify the reported failure and identify the component failure mode, failure mechanism and cause of the failure. Through comprehensive and systematic failure analysis, it can identify the causes of failure, provide guidance for device design, manufacturing process, experiment or application improvement, and help take appropriate corrective measures to eliminate the causes of failure mode or mechanism, so as to realize the device reliability improvement.