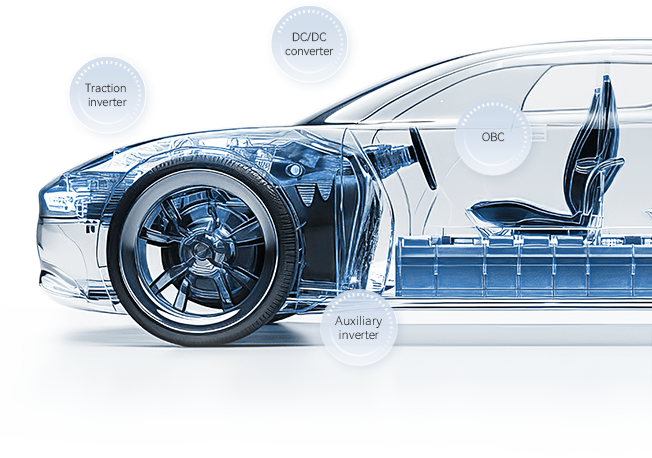

In light of the increasingly stringent carbon emission standard, the demand for widespread adoption of new energy vehicles (NEVs) is accelerating in the world, and replacing gasoline-powered cars has become an inevitable trend. Now silicon-based devices are primarily used in electric vehicles (EVs), but they generate a tail current, cannot raise the switching frequency, significantly increase loss in high-voltage and high-speed switching, and cannot improve power density nor reduce vehicle size and weight. SiC devices have the characteristics of high bandgap width, high saturation rate and high thermal conductivity, and can achieve high-speed switching, and reduce overall loss by more than 50% compared with silicon-based devices. They help increase the EV driving range, meet the 800V HV requirement, make the system lightweight, and solve three major pain points of EVs. Power devices, whose on-board applications mainly includes traction inverter, on-board charger and DC/DC converter, have a wide range of usage scenarios. Therefore, SiC devices are expected to be used at scale in the backdrop of the rapid development of NEVs.