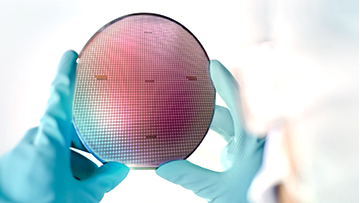

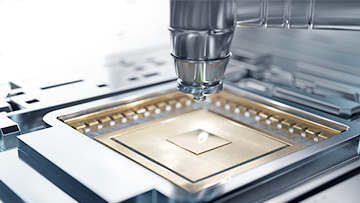

The epitaxial growth technology is an indispensable part of manufacturing silicon carbide (SiC) devices at present. The SiC epitaxial wafer refers to a specific single-crystal film grown through the epitaxy process on the basis of SiC substrate, which has consistent lattice, high purity and low defects. Today, the metalorganic chemical vapor deposition (MOCVD) is the most popular 4H-SiC epitaxial growth method. The upside is that the method can effectively control gas source flows, reaction chamber temperature and pressure in the growth process, change the film-forming environment, and accurately control the epitaxial growth parameters. The method has the excellent characteristics of good repeatability and moderate equipment size.